The Complexities Of Automating Nike Sneaker Manufacturing Processes

Table of Contents

Technological Hurdles in Automating Sneaker Production

Automating the production of a Nike sneaker, a seemingly simple product, presents a surprisingly complex technological challenge. The process involves a multitude of materials and intricate assembly steps, each demanding high precision and flexibility.

The Complexity of Material Handling

Automating the handling of diverse materials is a major obstacle. Nike sneakers utilize a variety of materials, including leather, synthetics, textiles, and foams, each with its unique properties and shapes. This heterogeneity presents significant challenges for automated systems.

- Precise cutting of irregular leather pieces: Achieving consistent cuts on irregularly shaped leather pieces requires advanced robotic systems with sophisticated vision capabilities.

- Consistent feeding of materials into automated machines: Ensuring a steady and reliable flow of materials into automated stitching, gluing, and assembly machines is crucial for maintaining production efficiency.

- Automated quality control for material defects: Identifying and rejecting defective materials before they enter the production process is essential for maintaining quality standards.

Overcoming these challenges requires advanced robotics and AI-powered vision systems. Collaborative robots (cobots), designed to work alongside human workers, and computer vision systems, capable of identifying and analyzing material properties, are key technologies in this endeavor.

Precision and Accuracy Requirements

Nike sneakers are known for their comfort and performance, demanding extremely high precision in manufacturing. Even slight inconsistencies in stitching, gluing, or component alignment can negatively impact the final product.

- Automated stitching: Maintaining consistent stitch length, tension, and alignment is critical for the durability and aesthetics of the sneaker.

- Gluing: Precise and consistent adhesive application is essential for the structural integrity of the shoe.

- Pressure application: Controlled and precise pressure application during assembly is necessary to ensure the components are properly bonded and aligned.

Current automation technology struggles to replicate the dexterity and precision of skilled human workers in these areas. While automation can assist in many aspects, human expertise remains crucial for final quality control and inspection, particularly for intricate assembly steps.

Adaptability to Changing Designs and Materials

Nike is famous for its frequent design updates and introduction of innovative materials. This necessitates highly adaptable automated systems capable of quickly adjusting to new production requirements.

- Re-programming robots for new models: Adapting robot programs to accommodate new designs requires significant reprogramming and testing.

- Re-calibrating automated systems for different materials: Automated systems must be recalibrated to handle changes in material properties, such as thickness, texture, and elasticity.

- Managing inventory for a vast range of parts: Efficient inventory management is crucial for ensuring the timely supply of parts for different sneaker models.

Therefore, the future of automating Nike sneaker manufacturing lies in flexible and reconfigurable automation systems. These systems must be capable of quickly adapting to changes in design, material, and production volume, minimizing downtime and maximizing efficiency.

Economic and Logistical Considerations

While automation offers significant potential benefits, the implementation of automated systems in Nike sneaker manufacturing also presents considerable economic and logistical challenges.

High Initial Investment Costs

The upfront investment required for advanced automation technology is substantial. This includes the cost of purchasing and integrating robots, AI systems, software, and other advanced equipment, along with the extensive employee training necessary to operate and maintain these systems.

- Robotics: The cost of purchasing and installing industrial robots can be significant.

- AI systems: Developing and implementing AI-powered vision and control systems requires substantial investment.

- Software: Specialized software for robot programming, production planning, and data analysis is essential.

- Integration: Integrating different automated systems into a cohesive production line requires extensive engineering expertise.

- Employee Training: Training employees to operate and maintain these complex systems necessitates significant investment in training programs.

A thorough return on investment (ROI) analysis is crucial before undertaking large-scale automation projects, carefully weighing initial costs against potential long-term savings in labor, material waste, and production time.

Workforce Transition and Reskilling

Implementing automation will inevitably impact the existing workforce. Strategic workforce planning, including retraining and reskilling programs, is essential to mitigate potential job displacement and to capitalize on the benefits of human-robot collaboration.

- Potential job displacement: Automation may lead to the displacement of workers in certain roles.

- Upskilling workers for new roles: Existing workers need to be retrained to operate and maintain new automated systems, and to take on higher-skilled roles in the automated factory.

- Human-robot collaboration: Creating a collaborative environment where humans and robots work together efficiently is crucial for maximizing the benefits of automation.

Investing in employee training and development is vital for ensuring a smooth transition to automated manufacturing and for fostering a skilled workforce capable of leveraging the benefits of the new technologies.

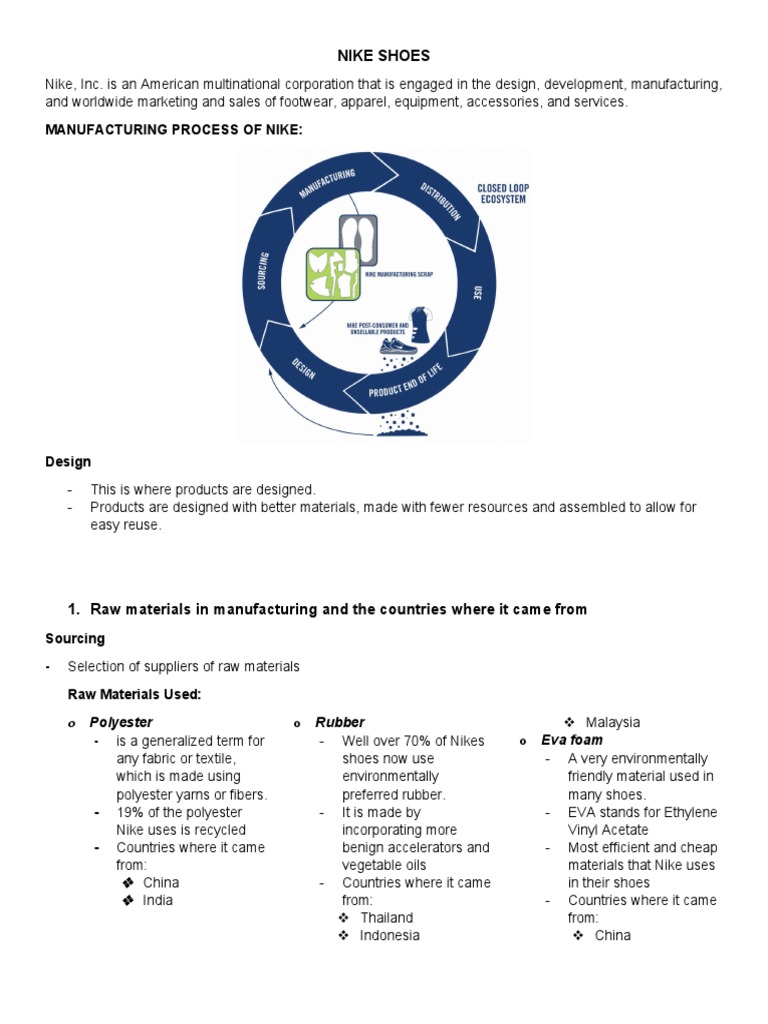

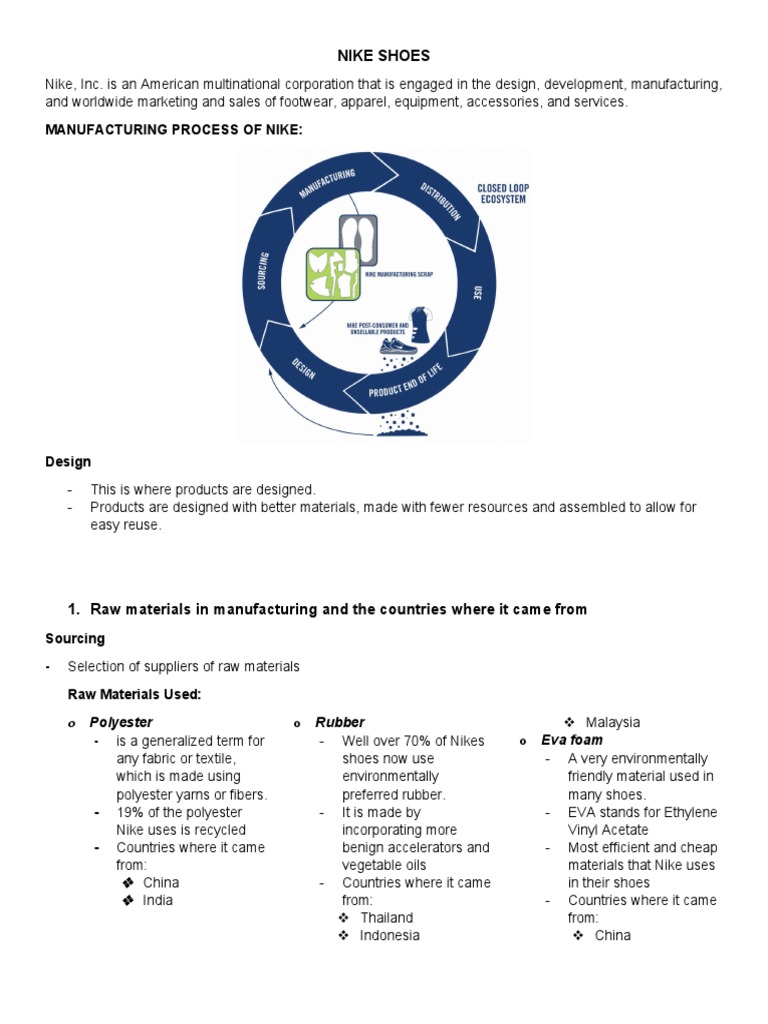

Supply Chain Integration

Integrating automated manufacturing processes into Nike's complex global supply chain presents significant challenges. This requires seamless synchronization of automated systems across different factories and locations, along with robust inventory management and quality control systems.

- Synchronization of automated systems across different factories: Ensuring that automated systems across different factories are synchronized and communicate effectively is critical for maintaining efficient production flow.

- Managing inventory across the global network: Efficient inventory management is crucial for ensuring that parts are available when and where they are needed.

- Maintaining consistent quality across different locations: Maintaining consistent quality standards across different manufacturing locations is essential for ensuring brand consistency.

Robust supply chain management systems and real-time data analytics are essential for effectively supporting automated manufacturing across a globally dispersed production network.

Conclusion

Automating Nike sneaker manufacturing processes holds immense potential for increasing efficiency, improving quality, and reducing costs. However, as detailed above, the journey is fraught with significant technological, economic, and logistical challenges. From the complexity of handling diverse materials and achieving high precision to the substantial investment costs and the need for workforce transition, success requires careful planning, significant investment, and a strategic approach to integrating automation into the existing ecosystem. To further explore the intricacies of automating Nike sneaker manufacturing processes and the future of automated manufacturing in the footwear industry, consider researching industry reports and case studies on advanced manufacturing technologies.

Featured Posts

-

Overcoming The Challenges Of Robotic Nike Shoe Manufacturing

Apr 22, 2025

Overcoming The Challenges Of Robotic Nike Shoe Manufacturing

Apr 22, 2025 -

Russias Aerial Assault On Ukraine Us Peace Plan Faces Steep Odds

Apr 22, 2025

Russias Aerial Assault On Ukraine Us Peace Plan Faces Steep Odds

Apr 22, 2025 -

Google And Doj Return To Court Battle Over Search Monopoly Heats Up

Apr 22, 2025

Google And Doj Return To Court Battle Over Search Monopoly Heats Up

Apr 22, 2025 -

Circumventing Trump Tariffs The Rise Of Advice Videos On Tik Tok

Apr 22, 2025

Circumventing Trump Tariffs The Rise Of Advice Videos On Tik Tok

Apr 22, 2025 -

Selling Sunset Star Accuses Landlords Of Price Gouging Amidst La Fires

Apr 22, 2025

Selling Sunset Star Accuses Landlords Of Price Gouging Amidst La Fires

Apr 22, 2025