Robotic Automation In The Footwear Industry: The Case Of Nike

Table of Contents

Nike's Adoption of Robotic Automation

Nike's commitment to robotic automation isn't just a trend; it's a strategic imperative. The company has invested heavily in automated systems throughout its supply chain, from design and prototyping to manufacturing and distribution. This involves the strategic implementation of sophisticated robotics solutions to handle various tasks within its shoe manufacturing process. While Nike doesn't publicly disclose every detail of its automation strategy, observable implementations and industry reports provide valuable insights.

- Specific examples of robotic systems used in Nike factories: This includes advanced robotic arms for precise assembly tasks, automated cutting machines for increased speed and accuracy in material processing, and automated quality control systems to minimize defects.

- Description of tasks automated: Robotic automation has streamlined processes such as cutting leather and synthetic materials, stitching uppers, assembling shoe components, and even packaging finished products.

- Quantifiable results of automation: While precise figures are often proprietary, reports suggest significant improvements in production speed (estimated increases of 20-30% in certain processes), a marked reduction in defects, and an enhanced level of worker safety by automating repetitive and potentially hazardous tasks.

- Mention of any partnerships with robotics companies: Nike likely collaborates with various robotics companies to develop and implement custom solutions tailored to its specific needs. While details of these partnerships aren't always public, collaborations are crucial to successful automation integration.

Benefits of Robotic Automation for Nike

Nike's investment in robotic automation has yielded substantial benefits across its operations. The positive impact is multifaceted, extending beyond mere cost savings.

- Increased production output and speed: Automated systems significantly boost production capacity, enabling Nike to meet the ever-growing global demand for its footwear.

- Reduced labor costs and operational expenses: While initial investment is substantial, automation leads to long-term cost savings by reducing labor costs, minimizing material waste, and increasing overall efficiency.

- Improved product quality and consistency: Robots perform tasks with greater precision and consistency than humans, leading to a higher quality product with fewer defects. This contributes to improved customer satisfaction and brand reputation.

- Enhanced worker safety: Automating dangerous or repetitive tasks, like working with heavy machinery or performing intricate stitching for prolonged periods, greatly improves the safety of Nike's workforce.

- Improved supply chain flexibility and responsiveness: Automated systems allow for better inventory management, faster order fulfillment, and increased responsiveness to changing market demands. This contributes to greater supply chain agility.

- Increased precision and accuracy in manufacturing processes: Robotic automation minimizes human error, resulting in consistent product quality and reduced waste.

Improved Supply Chain Management through Automation

Robotic automation isn't confined to the factory floor; it extends throughout Nike's entire supply chain.

- Automated warehousing and inventory management systems: Automated warehouses utilize robots for efficient storage, retrieval, and movement of materials, optimizing inventory levels and reducing storage costs.

- Automated material handling and transportation within factories: Robots streamline the flow of materials within factories, minimizing delays and improving overall production efficiency.

- Optimized logistics and distribution networks: Automation enhances the efficiency of logistics and distribution, enabling faster delivery times and reduced transportation costs.

- Improved traceability and tracking of materials and products: Automated systems enhance traceability, ensuring product quality and facilitating efficient recall processes if necessary. This promotes transparency and strengthens supply chain integrity. This is crucial for just-in-time manufacturing strategies.

Challenges and Future Trends in Robotic Automation for Nike and the Footwear Industry

While the benefits of robotic automation are clear, challenges remain.

- High upfront investment costs: Implementing robotic automation requires significant capital investment, potentially creating a barrier for smaller footwear companies.

- Need for specialized training and skilled workers: Operating and maintaining robotic systems requires skilled technicians and engineers, creating a demand for specialized training programs.

- Potential for job displacement and the need for workforce retraining: Automation may lead to job displacement in some areas, requiring proactive measures for workforce retraining and upskilling to adapt to new roles within the industry.

- Integration of artificial intelligence and machine learning: AI and machine learning are increasingly integrated with robotic systems, enhancing their capabilities and adaptability. This trend promises to further optimize manufacturing processes.

- The rise of collaborative robots (cobots) for safer human-robot interaction: Cobots are designed to work safely alongside humans, fostering collaboration and addressing concerns about job displacement.

Conclusion

Robotic automation is revolutionizing the footwear industry, and Nike is a clear leader in this transformation. The company's adoption of robotic automation has demonstrably improved efficiency, enhanced product quality, strengthened supply chain management, and boosted worker safety. While challenges such as high initial investment costs and workforce retraining are important considerations, the long-term benefits are undeniable. Embrace robotic automation for a more efficient and innovative footwear future. Explore the potential of robotic automation to transform your footwear manufacturing processes and gain a competitive edge in this dynamic industry.

Featured Posts

-

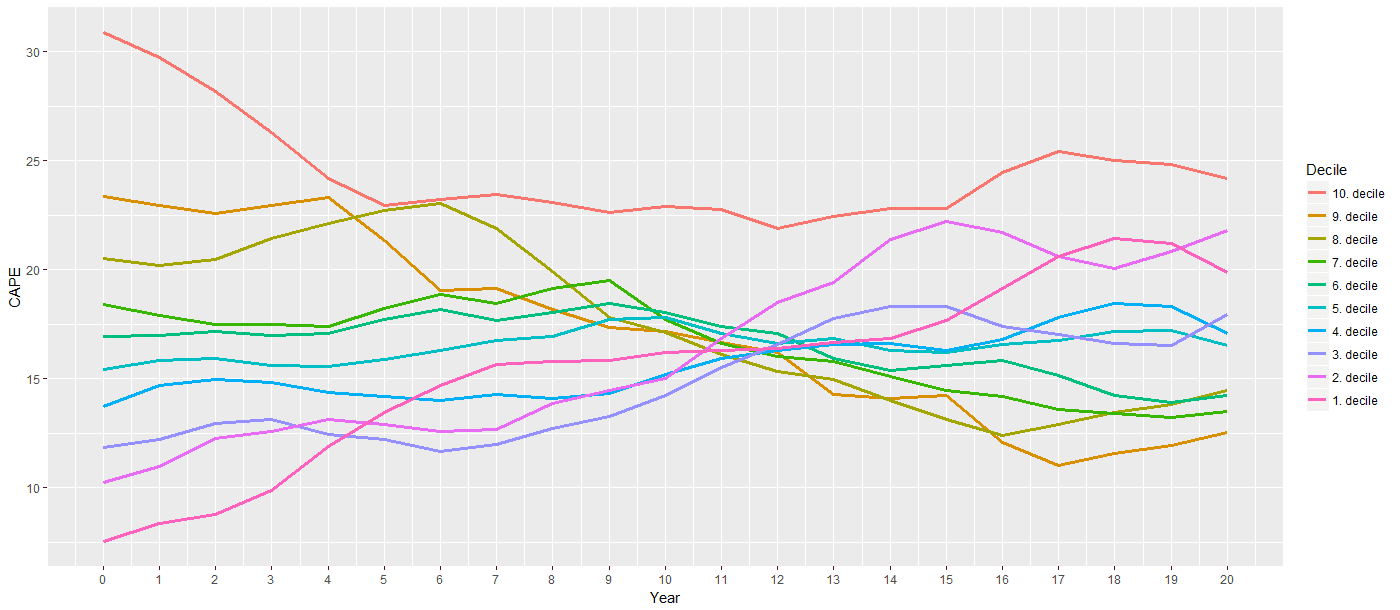

Why Investors Shouldnt Fear High Stock Market Valuations Bof As Perspective

Apr 22, 2025

Why Investors Shouldnt Fear High Stock Market Valuations Bof As Perspective

Apr 22, 2025 -

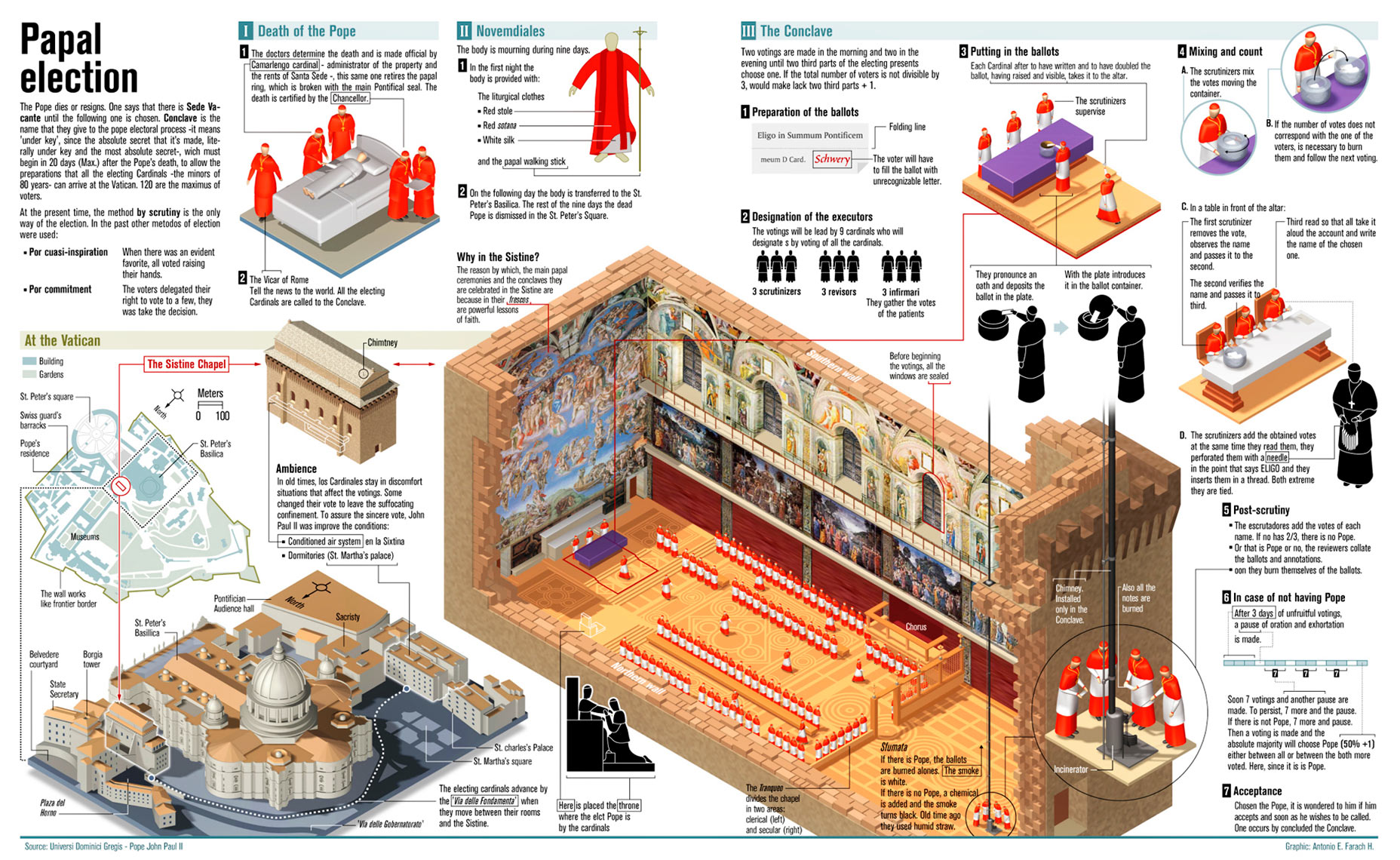

Will The Next Pope Continue Franciss Vision The Conclaves Challenge

Apr 22, 2025

Will The Next Pope Continue Franciss Vision The Conclaves Challenge

Apr 22, 2025 -

Papal Conclaves Explained The Process Of Electing A New Pope

Apr 22, 2025

Papal Conclaves Explained The Process Of Electing A New Pope

Apr 22, 2025 -

Closer Security Collaboration Between China And Indonesia

Apr 22, 2025

Closer Security Collaboration Between China And Indonesia

Apr 22, 2025 -

Stock Market Today Dow Futures Dollar And Trade War Impact

Apr 22, 2025

Stock Market Today Dow Futures Dollar And Trade War Impact

Apr 22, 2025